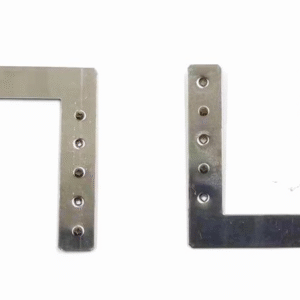

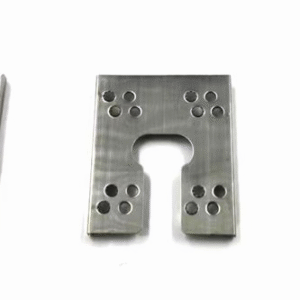

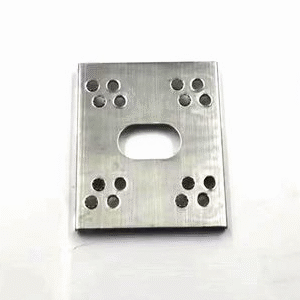

Jiujin Electric Power’s Solar Grounding Plate is engineered to provide reliable and low-resistance earthing for solar energy systems. Fabricated from high-purity copper or copper-clad steel, this plate offers excellent electrical conductivity and corrosion resistance, critical for long-term performance in outdoor environments. The design includes pre-drilled holes for easy connection to grounding conductors and secure installation in soil or concrete. A protective coating (e.g., electrolytic plating or anti-oxidation treatment) prevents degradation from moisture, chemicals, and soil acidity. Manufactured in our Hebei facility with precision quality control, this grounding plate meets international safety standards (e.g., IEC 62548, UL 467) and is essential for dissipating fault currents, lightning strikes, and static charges, ensuring system safety and longevity.

Varieties & Types Table

| Feature / Type | Specifications & Options Available by Jiujin Electric Power |

|---|---|

| Model/Type | GP-C100, GP-CCS120 (Denotes material and size) |

| Material | Pure Copper (C10100) or Copper-Clad Steel |

| Standard | Complies with IEC 62548, UL 467, IEEE 80 |

| Coating/Finish | Electrolytic Copper Coating or Anti-Oxidation Treatment |

| Size / Dimensions | 100mm x 100mm to 300mm x 300mm; Thickness: 3mm–6mm |

| Conductivity | Low resistance (<5 ohms per standard testing) |

| Packaging | Individual plates with protective wrapping; cartons or bulk boxes |

Applications of Use

-

Solar Farm Grounding: Earthing for utility-scale photovoltaic installations

-

Rooftop Solar Systems: Safety grounding for residential and commercial arrays

-

Lightning Protection: Dissipating lightning strikes to protect solar infrastructure

-

Equipment Safety: Grounding inverters, combiner boxes, and mounting structures

-

Corrosive Environments: Coastal or industrial areas due to protective coatings

-

Retrofitting Projects: Upgrading existing systems to meet safety standards

-

Renewable Energy Compliance: Ensuring adherence to local and international electrical codes