The Stay Assembly Complete is an essential structural component widely used in construction, utility pole installations, and cable support systems. It consists of multiple parts, including the stay rod, stay bow, base plate, and stay thimble, working together to provide stability and tension resistance. This article explores the components, functions, installation procedures, and key considerations for ensuring a secure and durable stay assembly.

Components of Stay Assembly Complete

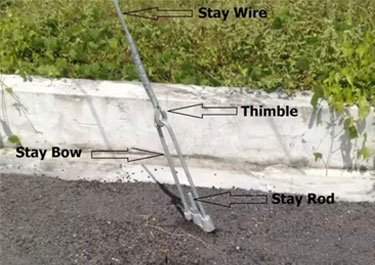

1.Stay Rod

A threaded steel rod that serves as the primary tension-bearing element.

Typically made of high-strength galvanized steel to resist corrosion.

Available in various lengths and diameters depending on load requirements.

2.Stay Bow (or Stay Hook)

A curved or U-shaped component that connects the stay rod to the anchor point.

Helps distribute tension evenly and prevents cable slippage.

3.Base Plate

A flat metal plate installed at the ground level to anchor the stay assembly.

Provides a stable foundation and prevents the stay rod from sinking into soft soil.

4.Stay Thimble

A metal loop or eyelet used to secure the guy wire or cable.

Protects the cable from abrasion and ensures a smooth connection.

Additional accessories may include nuts, washers, and anchor bolts for reinforcement.

Purpose and Functions

The Stay Assembly Complete is primarily used for:

Supporting Utility Poles & Towers – Prevents tilting or collapse due to wind or cable tension.

Stabilizing Guy Wires – Ensures overhead cables (e.g., power lines, telecommunication wires) remain taut and secure.

Structural Reinforcement – Used in construction to brace temporary or permanent structures.

Load Distribution – Transfers tension forces from cables to the ground efficiently.

Without a properly installed stay assembly, structures may become unstable, leading to safety hazards and structural failures.

How to install the stay rod?

- Site Preparation

Survey the location to determine soil stability and load requirements.Clear obstructions and ensure proper alignment with the structure being supported.

- Anchor Installation

Dig a hole deep enough to accommodate the base plate and stay rod.

Insert the stay rod into the ground at the recommended angle (typically 45°–60°).

Secure the base plate with concrete or compacted soil for stability.

- Attaching Stay Bow & Thimble

Connect the stay bow to the top end of the stay rod.

Loop the guy wire through the stay thimble and fasten it securely.

- Tension Adjustment

Use turnbuckles or tensioning devices to adjust the cable tightness.

Ensure even force distribution to avoid overloading one side.

- Final Inspection

Check all connections for tightness and corrosion resistance.

Verify that the stay rod is firmly anchored and the cable is properly tensioned.

Key Considerations & Safety Measures

1.Material Quality

Use galvanized or stainless steel components to prevent rust and degradation.

2.Soil Conditions

Soft or loose soil may require deeper anchoring or concrete reinforcement.

3.Load Capacity

Ensure the stay assembly can withstand expected wind and cable tension loads.

4.Regular Maintenance

Inspect for wear, corrosion, or loosening over time.

Replace damaged parts immediately to prevent failure.

5.Safety Precautions

Follow local regulations and engineering standards.

Use proper tools and protective gear during installation.

Conclusion

The Stay Assembly Complete is a critical system for maintaining structural integrity in utility poles, towers, and cable installations. By understanding its components, functions, and proper installation techniques, engineers and construction professionals can ensure long-term stability and safety. Proper material selection, correct installation, and routine maintenance are key to maximizing the assembly’s performance and durability.

By adhering to these guidelines, construction and utility projects can achieve reliable and secure structural support, minimizing risks and enhancing operational efficiency.